Lean implementation and optimisation

Is lean management the only solution?

We help business owners, management boards,and production directors eliminate wasteand increase their process efficiency to earn and save money

We are the Institute to Develop:

Production

Improvement is not only about implementing lean management. First of all, it is important to properly identify the areas that need improvement. The use of lean management tools and methods is very helpful, but not every company is ready for them. 5S, TPM, kanban, hoshin kanri, heijunka, A3, PDCA and other methods are also effective without changing the organisational culture. The most important thing is to adjust the method to the needs of the organisation.

Processes

It is not only manufacturing that can be improved: office, customer service, administration, warehouse, sales, purchasing – wherever a process is carried out, it can be improved. This does not always mean implementing lean management. Rather, simply describing the processes helps to improve them so that when you start to measure and manage them, you see further improvement very quickly. From here, it is only a step to systemic improvement.

Planning

The heart of any company beats as hard as its operations are planned. The most important thing in planning is regularity. The proper planning of work brings about results, while effectiveness is ensured by measuring the implementation of the plan. The basis of lean management, i.e. the standardisation of work, is crucial here and ensures effective operation. While a plan is crucial, it is sometimes more important to be agile and responsive.

People

People are the most important part of the company and they work best when they become a team. Teamwork, communication, problem solving, and building awareness of waste are often overlooked aspects of implementing lean management. Training and supporting people, as well as providing them with a thriving environment, makes the company as unsurpassed as Toyota. Working in a culture of continuous improvement provides real strength.

Performance

Transforming the entire organisation is difficult. This transformation is much easier to carry out when you have clearly defined goals, the right strategy, and measures that will help determine the direction. No change, let alone the implementation of lean management, makes sense without a strategy. It only becomes a façade or an incompletely implemented tool-based program. It is necessary to define strategies and goals in order to choose the right tools and techniques.

Lean is fine! Solutions and methods help many companies. However, not everyone can apply this philosophy, not everyone is ready to constantly improve, and many managers are not ready for systemic improvement. Only a small percent of Polish companies are on the right track: on a road where the process is more important than the result. Fortunately, not everyone has to be lean. At the Institute of Development of Production, we focus on helping companies to simply become better. Good work organisation, one team, and clear rules mean better results: lower costs, higher income, and joy at work.

Trust our experience, methods, and skills, or find out about them in a short conversation.

FREE 30-MINUTE

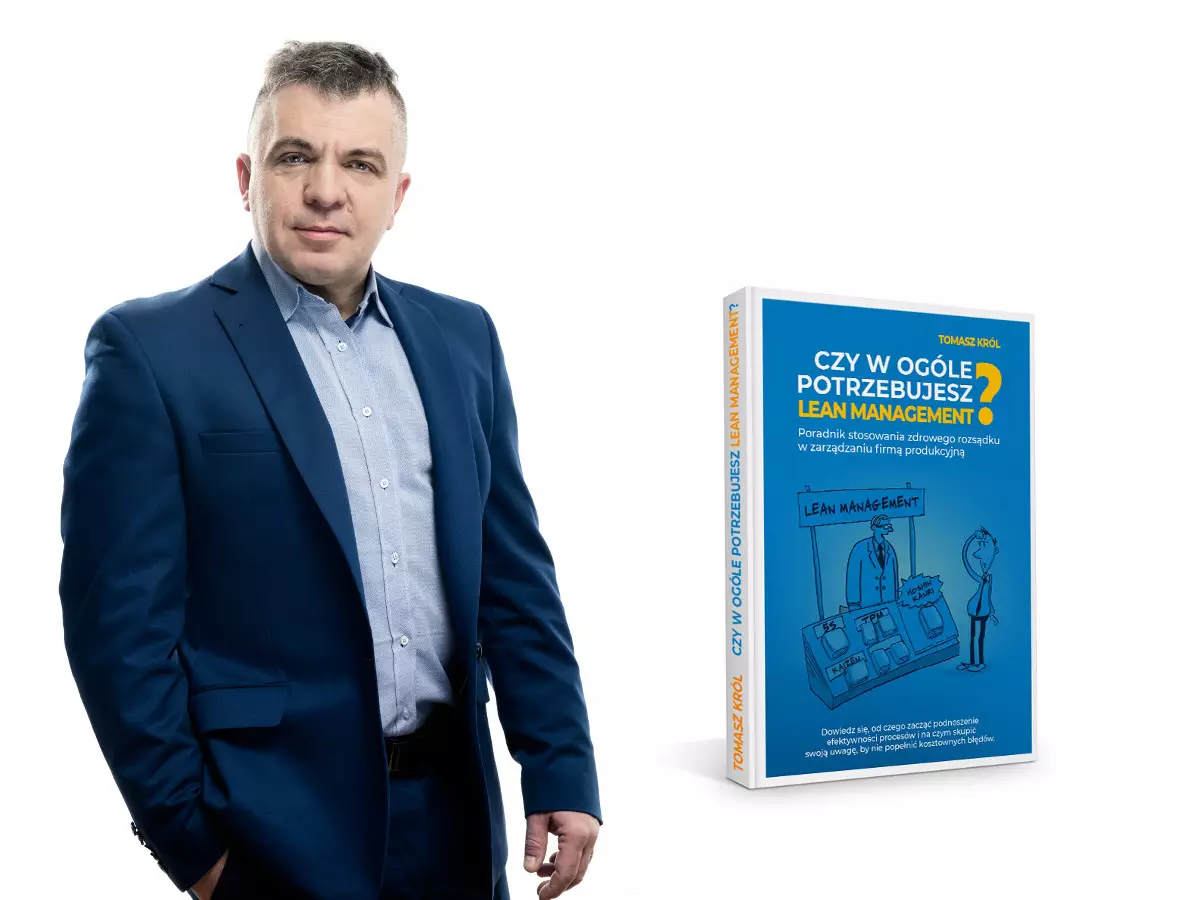

meeting with Tomasz Król

As part of the conversation, I have a gift for you – my e-book "Do you even need Lean Management?" – in Polish.